|

|

|

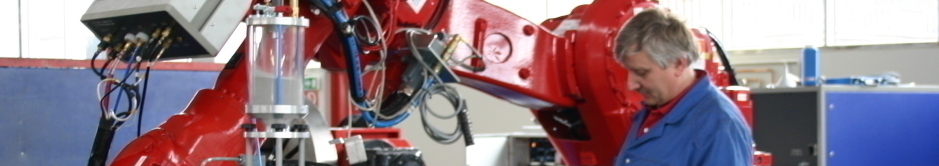

IMC-Weld cladding |

|

|

|

|

|

For special purpose like wear or corrosion resistance, we may provide our know-how and our advanced equipment for weld cladding. |

|

|

|

|

|

|

|

PTA weldingPTA welding is done fully-automatically by a 12-axis robot. Here are the key facts: max. Ø: 3500 mm (137.8 inch) max. length: 10,000 mm (393.7 inch) max. piece weight: 10 t Inside welding: from ø70 mm (2.76 inch) to 3000 mm (118.11 inch) length |

|

|

|

Advantages of this procedure:· Low fusion degree (ca. 5%) · Small heat affected zone · Wide range of materials

|

|

Typical applications: · Stelliting of valve parts · Cladding of extruder screws with tungsten carbide · Inside cladding of tubes from DI 70 mm (2.76 inch) · Weld cladding of forging dies

|

|

|

|

|

|

|

|

MAG-CladdingUP-Band cladding

Typical applications: · Weld cladding of forging dies against wear · Weld cladding of chutes for cement industry against wear · Band cladding of HD reactors in cause of corrosion · etc.

|

|

|

|

|

|

Inside cladding of tubes with highly wear-resistant filler metal (55-60 HRC) |

|

|

|

|

|

|

|

|

Flange plate MAG cladding with NIBAS 70/20 |

HD reactor UP cladding with Alloy 825 |